Inspired by his own struggles with expensive and poor fitting prosthetics, National

Park College (NPC) Engineering student, Ben Scarbrough hopes to use his degree to

design affordable, custom prosthetics and disability aids. He was born with campomelic

dysplasia, a rare disorder that affects the skeletal system. He uses prosthetic legs

for mobility but says quality prosthetics are too costly for most people.

Inspired by his own struggles with expensive and poor fitting prosthetics, National

Park College (NPC) Engineering student, Ben Scarbrough hopes to use his degree to

design affordable, custom prosthetics and disability aids. He was born with campomelic

dysplasia, a rare disorder that affects the skeletal system. He uses prosthetic legs

for mobility but says quality prosthetics are too costly for most people.

“They are so expensive, and I don’t think they should be that expensive. Because

of my experience with prosthetics, I believe I can probably make them cheaper and

be able to pass that on to people so they can have the newer technology,” Scarbrough

said. He explained that prosthetics with sensors and ankle movement can cost more

than $100,000. “I believe I could build that at a cheaper rate so people who aren’t

exactly wealthy could still be able to enjoy that.”

Scarbrough completed the Industrial Technology program as part of his degree path.

The certificate requires completion of a welding course. “Because my natural arms

are shorter than average, I would need to have prosthetics to be able to complete

the class. My insurance only offers one set of prosthetics every three years, and

I am in need of legs as well, as mine are breaking down,” he said.

Scarbrough is currently working with a team of peers to design custom prosthetic arms

that will allow him to participate in welding classes. He took the initiative to seek

design input from staff at the Innovative Technologies Center to refine his design

and has inquired about a grant for help funding the prototype. He worked with Industrial

Technology instructor Bill Frueck who advised the group and documented their work.

Frueck helped to clarify the mechanics needed to make the prosthetic electrically

functional. “I thought this would be a valuable project for my fellow engineering

students to assist me with as it would provide hands-on experience,” said Scarbrough.

The team included computer programming student Jordan Terry, computer engineering

student Mark McCorkle, industrial technology student Leslie Slife, electrical engineering

student Jason Redfield, and mechanical engineering student David Silk.

Scarbrough is currently working with a team of peers to design custom prosthetic arms

that will allow him to participate in welding classes. He took the initiative to seek

design input from staff at the Innovative Technologies Center to refine his design

and has inquired about a grant for help funding the prototype. He worked with Industrial

Technology instructor Bill Frueck who advised the group and documented their work.

Frueck helped to clarify the mechanics needed to make the prosthetic electrically

functional. “I thought this would be a valuable project for my fellow engineering

students to assist me with as it would provide hands-on experience,” said Scarbrough.

The team included computer programming student Jordan Terry, computer engineering

student Mark McCorkle, industrial technology student Leslie Slife, electrical engineering

student Jason Redfield, and mechanical engineering student David Silk.

“He has built, with his outgoing personality, a team of resources supporting his project.

Many engineering students choose the profession due to its high demand, high wage

outcome. Ben is designing an advanced prosthetic at an affordable price, and that

is a level of altruism that many beginning engineering students take years to develop,”

said professor Darlene Gentles.

“Since I have worn prosthetics my entire life, I am familiar with how the mechanics

work. I had an I-Limb hand, which is a hand that provides an articulation of each

finger. This spurred the idea of creating my own set of arms to be able to complete

the welding class,” added Scarbrough.

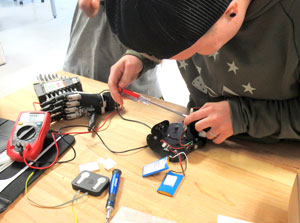

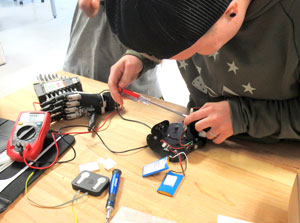

Scarbrough and his team used basic hand tools, 3D printers, a soldering iron, Arduino

circuitry, and stepper motors to build the prototype. Unfortunately, due to COVID-19,

all progress on the project ceased at the testing phase. The team is still testing

motors to identify a solution that will hold the right amount of torque, gear patterns,

circuitry, and programming.

Scarbrough and his team used basic hand tools, 3D printers, a soldering iron, Arduino

circuitry, and stepper motors to build the prototype. Unfortunately, due to COVID-19,

all progress on the project ceased at the testing phase. The team is still testing

motors to identify a solution that will hold the right amount of torque, gear patterns,

circuitry, and programming.

Scarbrough was selected to receive the Elisabeth Wagner Math and Science Scholarship

last semester. He said his college experience overall has been very positive and has

helped to boost his confidence to further his education. He said that since he began

classes, it has “re-sparked [his] passion” for learning. “I love the teachers. They

have all been very helpful and they all seem to really care about my success.” After

graduation, he plans to transfer to the University of Arkansas Little Rock to complete

his bachelor’s degree.